Flexible Packaging Quality Control for Outstanding Results

In the flexible packaging industry, quality control is key to competitiveness and customer trust. As leading manufacturers, we implement a rigorous system from raw material sourcing to delivery, ensuring our solutions meet international standards and exceed expectations.

Raw Material Control

- We strictly screen our suppliers to ensure that the raw materials used comply with the relevant standards in the food and pharmaceutical fields.

- All raw materials must pass a number of tests for environmental friendliness, functionality, physical properties, etc. to ensure that they comply with ISO9001 and other industry certification requirements.

- Each batch of raw materials is rigorously inspected and complete test reports are provided to ensure that they are free of defects and harmful substances.

Production Process Monitoring

- Automated production line: We have introduced advanced automated production equipment to monitor the production process in real time through an intelligent management system, which reduces human error and improves production efficiency.

- Real-time quality inspection: Each process is equipped with high-precision testing equipment, such as colorimeter, tensile tester, gas permeation tester, etc., to ensure that the products meet the standards during the production process.

- Midway sampling inspection: At each production stage, products are sampled and tested to ensure the stability and consistency of each batch.

Finished Product Inspection and Factory Inspection

- After the products are completed, we will carry out a comprehensive finished product inspection, including appearance inspection, size deviation, package sealing, breakage resistance, etc.

- Internationally certified laboratory equipment is used to conduct simulation tests on the finished products for high temperature resistance, cold resistance, humidity and chemical substance erosion.

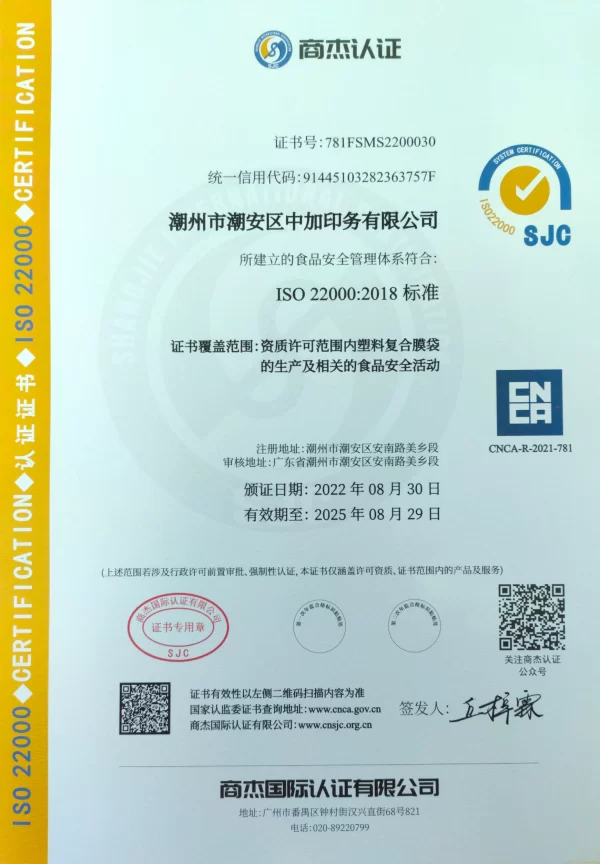

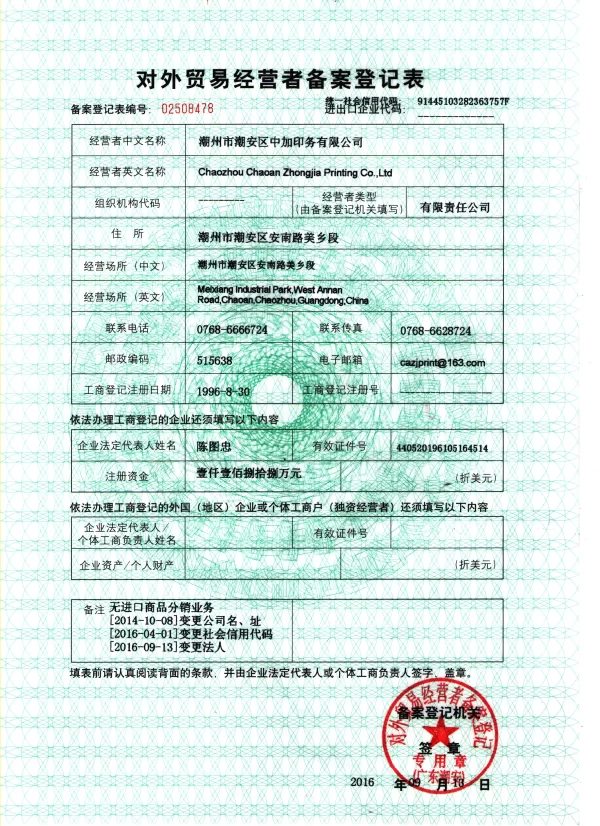

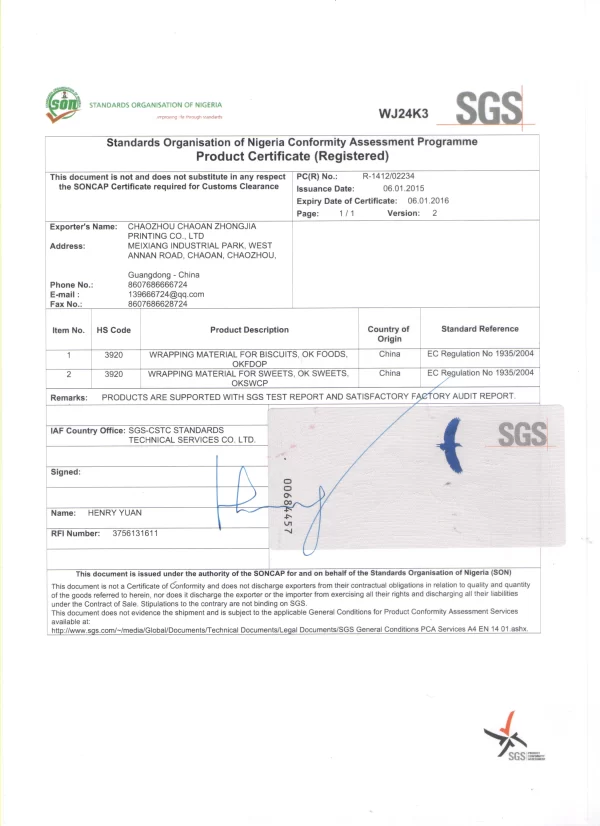

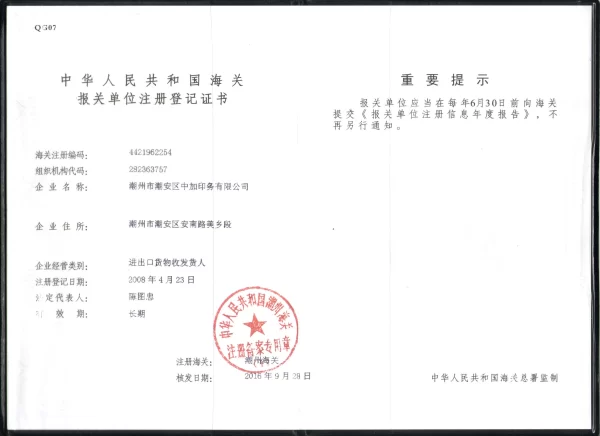

- All ex-factory products comply with international standards such as FDA, SGS, ISO22000, etc. Detailed quality reports and certificates are provided.

Quality Assurance Technology

We use advanced solvent-free laminating and water-based ink technologies to ensure packaging excellence in environmental protection, durability and aesthetics to meet the high standards of various industries.

Solvent-free Lamination and Water-based Ink Technology

- Solvent-free laminating technology meets the requirements of environmental protection and improves the mechanical properties and chemical resistance of packaging.

- Water-based ink reduces VOC emissions and reduces environmental pollution, while improving the quality and stability of printing, ensuring bright colors and durability.

Intelligent Quality Tracing

- Advanced quality traceability system, all production information can be recorded and tracked in real time, ensuring that each batch of products has a complete quality traceability record.

- Instant feedback is provided to ensure that any quality issues are identified and dealt with in a timely manner.

Start Your Flexible Packaging Journey with Zhongjia Printing

Contact Our Product Specialists Today

Complete Quality Inspections

We have established specialized laboratories to ensure the reliability of our flexible packaging solutions.

Air Tightness Test

A gas tightness tester ensures the bags are 100% airtight.

Chemical Residues Test

A gas chromatograph detects any chemical residues on the surface, ensuring safety.

Material Strength Test

A tensile tester checks the strength of raw materials to ensure the bag materials are strong enough.

Drop Test

Bags filled with 5L of contents are dropped from a height of 1 meter, 3-5 times, to test shelf durability.

Heat Seal Strength Test

Tests the strength of heat seals to ensure products remain intact during storage and transport.

Lamination Strength Test

A tensile tester measures the lamination strength of formed pouches to ensure usability.

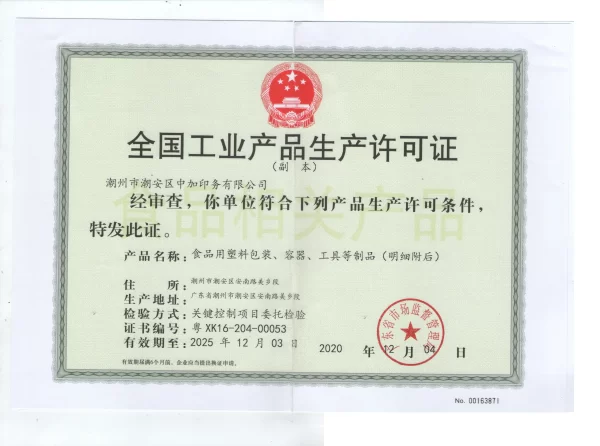

Flexible Packaging Quality: Certified Excellence

We ensures flexible packaging quality with ISO, HACCP, FSSC, BRC, and SMETA certifications. Trust us for reliable solutions from expert manufacturers.

Custom Your Own Flexible Packaging Solutions!

Make your brand's packaging even better with our custom pouch packaging services. Contact the team of professionals today for a Custom Flexible Packaging quote and free samples!