Strong Manufacturing Factory Capacity

Specialized production processes to provide efficient and environmentally friendly flexible packaging solutions to meet global packaging needs.

Efficient Flexible Packaging Production Expert

We specialize in the production of high-efficiency flexible packaging, relying on high-speed water-based ink printing machine, solvent-free laminating machine and other advanced equipment, using environmentally friendly ink printing system, low emissions and more environmentally friendly. The workshop is equipped with air-conditioning and purification room to ensure high quality and environmental protection requirements. With exquisite technology and strict management, we provide customers with high quality service and excellent value.

Eco-friendly Water-based Ink Printing Technology

The whole process adopts water-based ink printing and solvent-free laminating technology, which reduces pollution emissions and meets international environmental quality standards such as ISO9001-2018, providing customers with high-quality and sustainable packaging solutions.

View Water-based Ink Printing Process

0+ Years

of Experience

0 ㎡+

Factory Area

0+ Tons

Daily Production Capacity

0+

Employees

0

Production EquipmentAdvanced Factory Workshop

The production base covers an area of more than 6,000 square meters, with four fully automatic production lines and an annual production capacity of 5,800 tons. With advanced equipment and experienced team, we ensure efficient production with stable and high quality packaging products.

Incoming Material Workshop

Engraving Workshop

QS Clean Room

RCO Equipment

Printing Workshop

Laminating Workshop

Slitting Workshop

Bag Making Workshop

Laboratory

Warehousing Workshop

Complete Quality Inspections

We have established specialized laboratories to ensure the reliability of our flexible packaging solutions.

1.Preproduction Comunication

Confirmation of product size, material, printing content, special requirements, price and so on.

2.Plate Cylinder Production

Printing molds will be made precisely according to the required design.

3.Plate Proof Approval

Provide printing samples to confirm the text and pattern before production.

4.Printing

Water-based ink is printed onto the film by means of a cylinder.

5.Lamination

Glueing multiple layers of different films together.

6.Slitting

Cutting of products according to different sizes.

7.Bag Making

Making bags from different films according to different requirements.

8.Quality Control

Inspection before each shipment to ensure the quality of packaging.

9.Packing and Delivery

Check the bags and then pack and encapsulate them for delivery as per customer's requirement.

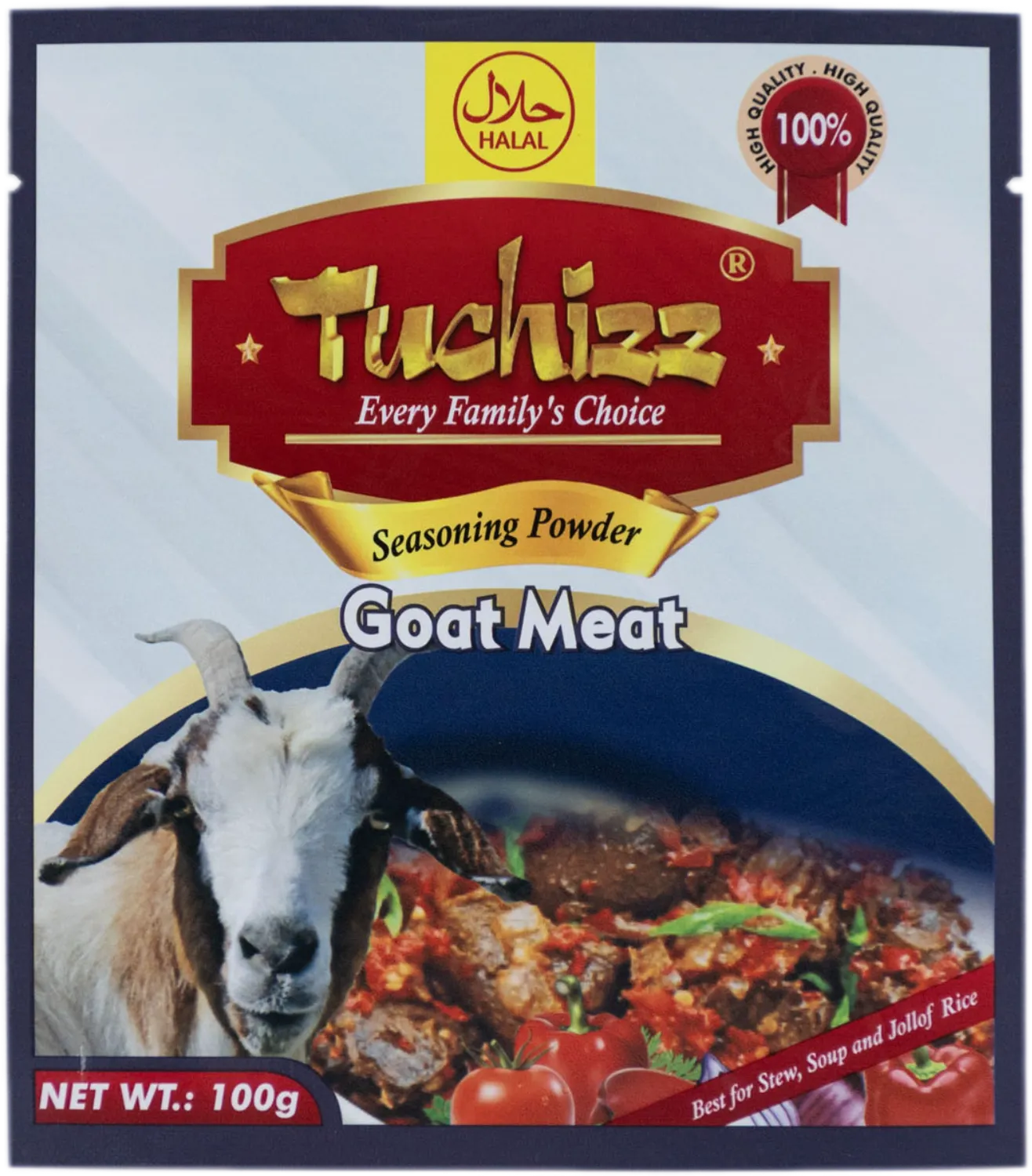

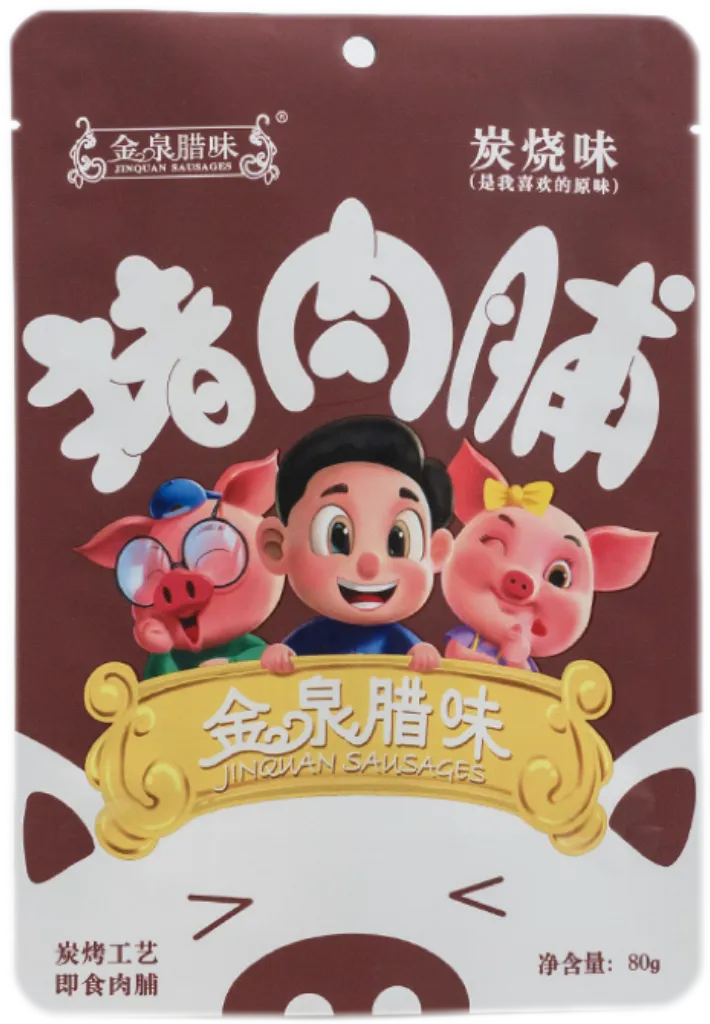

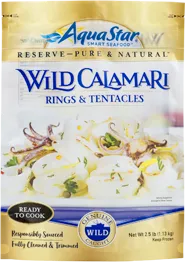

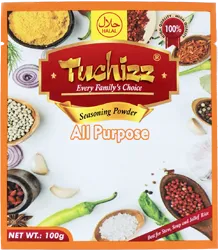

Printed Pouches and Packaging Case Styles

Start Your Flexible Packaging Journey with Zhongjia

Contact Our Product Specialists Today

CONTACT US

Request a Free Quote

We are committed to providing you with quality flexible packaging solutions. Please contact us and our team of professionals will be happy to assist you!