In the skincare market, facial mask pouch is not just packaging, it is also an important factor in consumers’ purchasing decisions. Quality skincare mask packaging can protect the essence of the mask while enhancing brand image and consumer trust.

Are you facing the following problems?

- Don’t know how to choose the right facial mask packaging?

- Want to reduce the cost but worry about compromising the quality of the packaging?

- Need to customize the packaging, but not sure which structure is more suitable?

Today, Zhongjia Printing will discuss the selection, design, and production of cosmetic mask packaging through real case studies, and help you find the most suitable customized cosmetic packaging solution.

Successful Case: How to Create a High-end Face Mask Pouch?

We have customized a high-end moisturizing face mask packaging for a famous brand with the following customer requirements:

- Ensure that the essence of the mask is not easy to evaporate and extend the shelf life of the product.

- Use of environmentally friendly materials, in line with international safety standards.

- Enhance the visual appeal and make the product more competitive in the market.

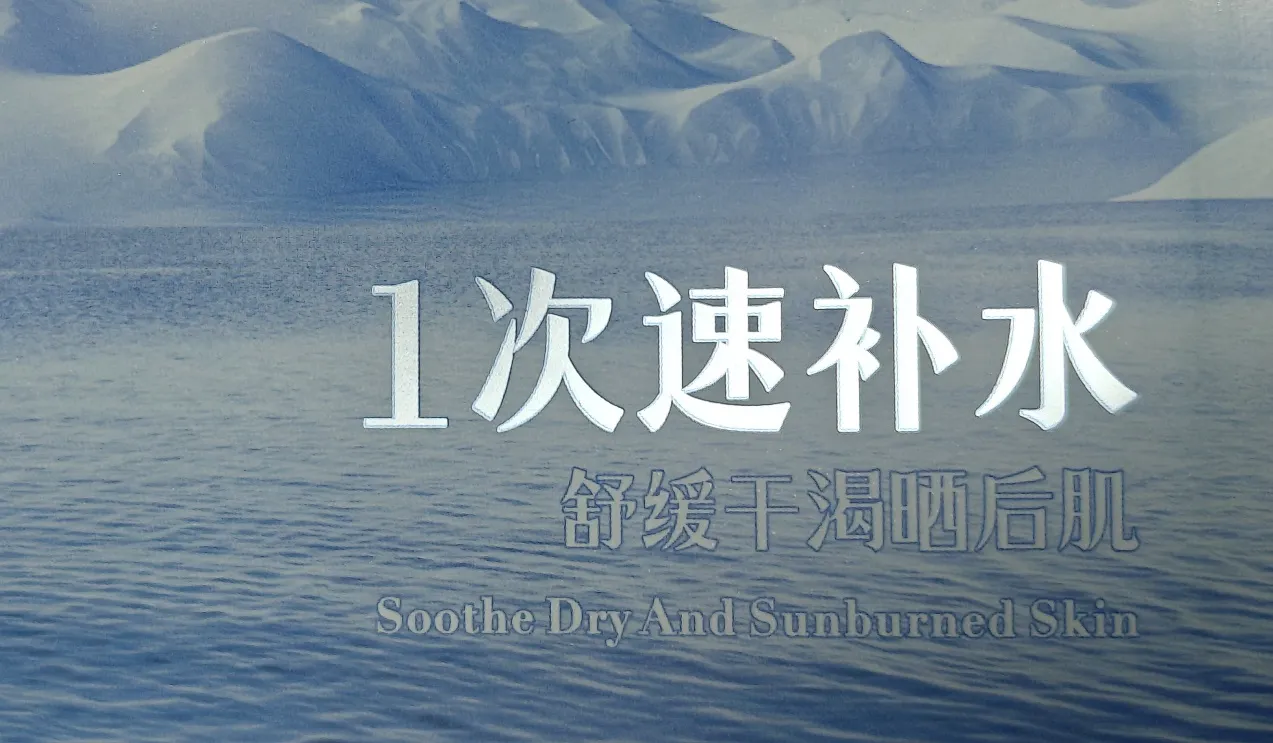

Visual Design: Enhance Brand Recognition

We adopt a blue color tone as the main body and use a water body design on the pattern so that the goods can remind people of the effect of moisturizing skin. Some customers also want to use the physical picture of dry skin, which is more shocking, but it may cause discomfort to the users, so it is not very recommended to use it.

Material Analysis: Three-layer Structure to Enhance Sealing Performance

Generally, high-grade mask products will use a three-layer structure design, the advantage of this design is that the bag has a hard feel while keeping the mask moist. The following is the product structure.

Printing Layer: BOPP (Bi-oriented Polypropylene)

The printing layer of the mask product will generally use BOPP material, this material has a variety of thicknesses, in the light into this material will produce refraction, there is a subtle expansion effect, so that the product has a more advanced texture.

At the same time, BOPP material has good water-blocking properties, can be a good barrier to moisture evaporation, very suitable for wet mask products.

Printing key point: BOPP material corona value is low, and water-based ink printing needs to be used with a corona machine.

Composite Layer: VMPET (Aluminized PET)

A composite layer will generally use VMPET material, this material is through the vacuum machine in the PET material plating a thin layer of aluminum layer, to increase the metal texture. At the same time, PET material has better water resistance performance.

Composite key point: Because the material has better water-blocking performance, you need to pay attention to the temperature change when compounding to ensure the adhesion and dryness of the glue, otherwise it will produce fine white spots, affecting product quality.

Inner Layer: BOPE/BOCPP (sealing layer)

The composite layer will generally use VMPET material, this material is through the vacuum machine in the PET material plating a thin layer of aluminum to increase the metal texture. At the same time, PET material has better water resistance performance.

Composite key point: because the material has better water-blocking properties, you need to pay attention to the temperature changes in the composite, to ensure that the adhesive viscosity and dryness, otherwise it will produce fine white spots, affecting product quality.

How to Reduce the Cost of Mask Packaging?

Customized packaging does not mean high cost! By optimizing the production process, you can effectively reduce the cost of mask packaging while ensuring quality.

✅ Printing with Water-based Ink: Compared with traditional solvent-based ink, water-based ink is environmentally friendly and non-toxic, which is suitable for mass production and can reduce printing costs.

✅ Solvent-free Laminating Technology: Through solvent-free laminating technology, we can improve the lamination quality of the packaging, while reducing the production cost and enhancing the environmental performance.

✅ Bulk Customized Production: through wholesale facial mask packaging supply mode, it can significantly reduce

Why Choose Us?

As a professional three-side facial mask packaging bag custom manufacturer, we specialize in customizing high-quality facial mask packaging, providing one-stop solutions for global brands.

Our Advantages

- Industry experience: more than 30 years of industry experience, serving internationally famous skincare brands.

- Eco-friendly materials: provide customized facial mask packaging bags, in line with international environmental standards.

- Efficient production: fully automated production line to ensure stable delivery time and help brands quickly capture the market.

- Customized design: support personalized printing, and help brands stand out.

If you want high-quality and customizable mask packaging, please contact us!

For a free quote and design proposal, please leave a message or email!