The modern packaging industry would not have churned out flexibility without flexible, flexible, and versatile packaging. Flexible packaging can now be used for everything, from food to pharmaceuticals, and daily necessities to industrial applications. This includes the application of advanced printing technologies, such as water-based ink printing, for which flexible packaging is to become the real heavyweight behind sustainable development. This article discusses issues such as the definition of flexible packaging, its material forms, emerging market trends, and environmental trends so that readers have a minimum idea of how to improve this field.

What is Flexible Packaging?

Flexible packaging is a type of packaging made of flexible packaging materials that is characterized by its ability to adapt its shape to the form of the product or outer pressure without compromising the structure of the package. Compared with rigid packaging like glass bottles and metallic cans, flexible packaging can meet more market demands due to its lightweight and flexibility.

Examples of the typical applications are food packages of flexible material packaging: stand-up pouches, flat bottom pouches, spout pouches, and so on, whose aim is to guarantee safe foods for longer while catering to consumers’ requirements with efficiency. Therefore, the meaning of what flexible packaging is refers not only to the aspect but also to the different variations of it.

Flexible Packaging Materials and Printing Technology

Most Common Flexible Packaging Materials

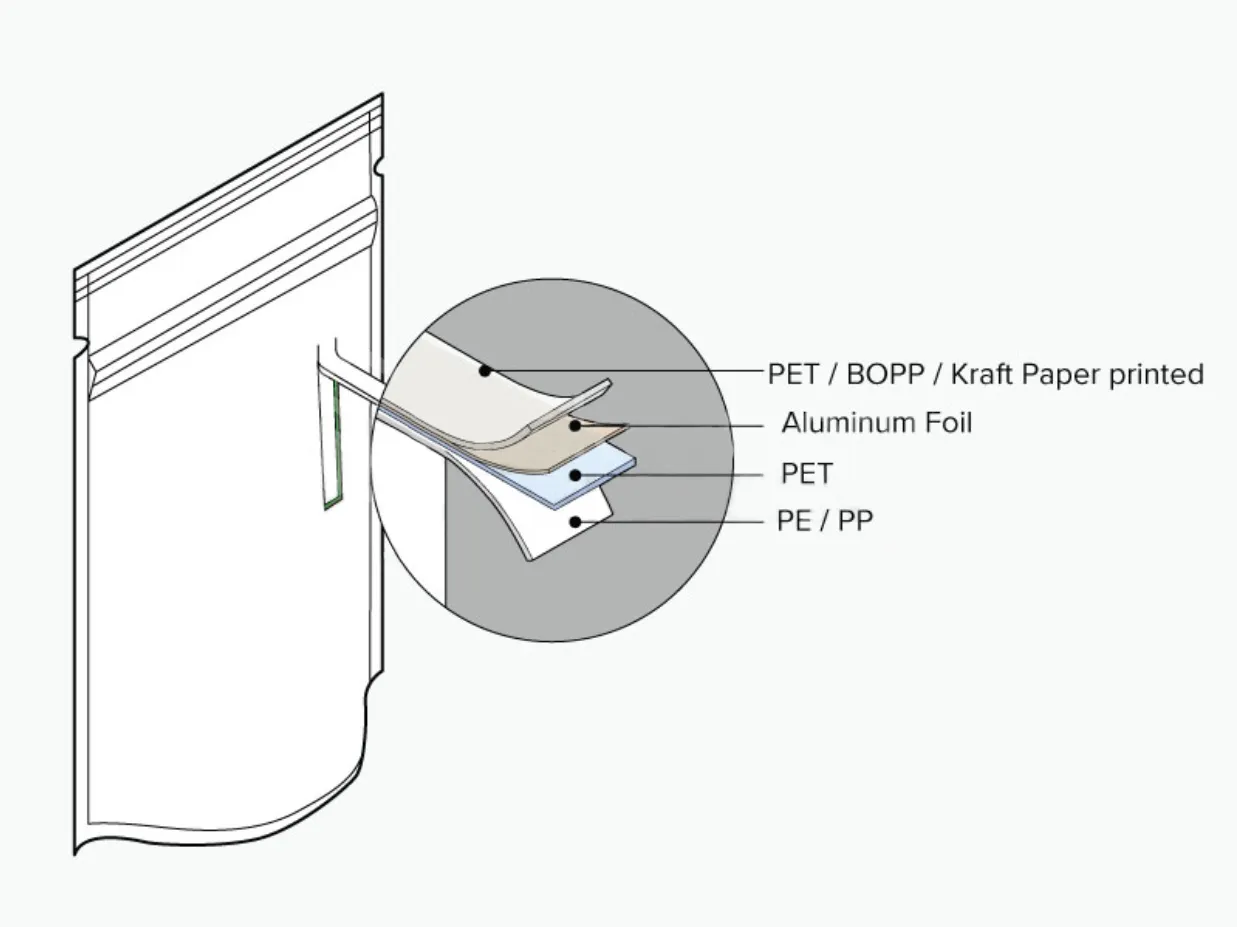

The Flexible Packaging Materials directly choose the packaging work, here are some of the core materials:

- Plastic films: polyethylene (PE) and polypropylene (PP) are the major components of flexible plastic packaging with good barrier properties, moisture resistance, and durability.

- Aluminum foil composites: have excellent light and oxygen barrier properties; use them widely in food and pharmaceutical packaging.

- Paper and biodegradable materials: In response to environmental demands, these materials play an important role in sustainable flexible packaging.

Merits of Water-based Ink Printing

Water-based ink is an environmentally friendly alternative to traditional solvent-based inks for printing materials. It is water-based as the main solvent, rather than chemicals such as alcohol or ketones, and has become a popular choice for packaging manufacturers seeking sustainable solutions.

In flexible packaging printing, the major area using water-based inks as the main propellant in promoting the environmental aspects is the emission of volatile organic compounds (VOCs) at very low levels. This can be applied even to printed flexible packaging for making graphics and text having qualities of environmental protection printing.

Market Trends and Customization in Flexible Packaging

The Growth of the Flexible Food Packaging Market

Food packaging remains the backbone of the contemporary flexible packaging Market, increasingly attracting consumers. The rapid increase in the demand for convenience foods and ready-to-eat products, along with the extensive changes taking place in flexible packaging, indicates a great future for flexible packaging and the food industry. Most importantly, flexible food packaging for snacks, frozen food, and beverages is on the rise.

The Rise of Customization in Flexible Packaging

Consumers and brands nowadays are looking for more than just functionality in today’s packaging requirements. Enhanced differentiation and brand expression are the real draws. This is how custom flexible packaging has evolved to become a trend. With superior quality design and printed flexible packaging, businesses can have an effective medium to convey brand concepts and attract consumer attention.

Flexible Packages Making an Eco-Friendly Statement

Lightweight and Eco-Friendly

Zhongjia printed flexible packaging bags allow economical weight saving in it. This saves transportation costs and cuts down carbon footprint. In comparison to other traditional rigid packaging formats, flexible packaging invariably uses less material, yet offers equal or greater protection. These manmade properties prove to be a great manifestation of eco-friendly flexible packaging.

The Quest for Sustainable Materials

The flexible packaging industry now widely advocates bio-based and recyclable consumption to serve up sustainable flexible packaging. An example of a biomaterial would be PLA (polylactic acid), which is finding its way into all types of flexible packaging.

Conclusion

As an important part of modern packaging, flexible packaging not only meets the diversified needs of consumers and enterprises with its multiple functions but also has become an important driving force for sustainable development because of its environmental properties. The flexible packaging market will continue to prosper with the advancement of technologies, especially in water-based ink printing, by offering effective and greener packaging solutions to food, pharmaceutical, and other industries.

For custom flexible packaging, or to learn more about flexible packaging materials, feel free to contact Zhongjia Printing. To explore unlimited possibilities in flexible packaging, get in touch with us, a professional flexible packaging manufacturer.