Due to climate change, the loss of biodiversity, and environmental pollution, humanity is turning the Earth into a fragmented and increasingly uninhabitable planet.

According to CNN, the United Nations has released a report on the health of the planet, stating that the Earth is facing three major crises—climate change, biodiversity destruction, and pollution—and that humanity must change its relationship with nature.

This marks the beginning of our environmental action.

The Challenge in Traditional Flexible Packaging Printing

The traditional flexible packaging printing industry is a highly polluting sector, producing numerous pollutants during the manufacturing process, such as volatile solvents like ethyl acetate. For years, achieving cleanliness, hygiene, and sustainability in the production process has been a significant pain point for the flexible packaging industry.

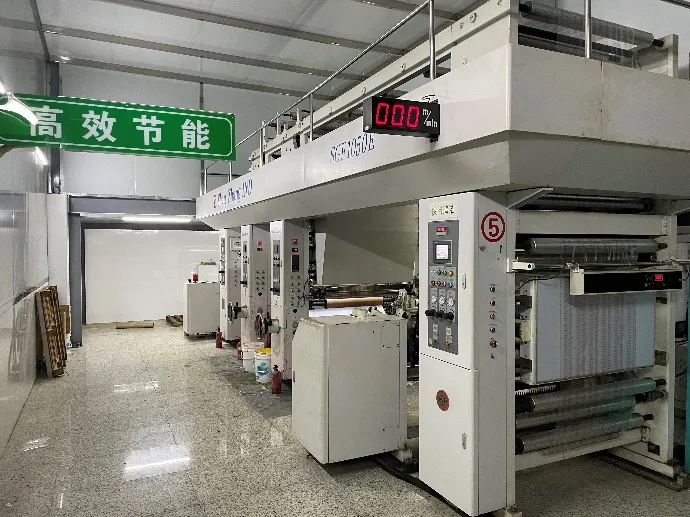

Since 2016, our company has initiated air pollution control efforts, installing Pollution Control Equipment like RCOs (Regenerative Thermal Oxidizers), in line with international environmental emission standards, controlling total VOCs emissions to below 120. However, over time, our pollution control equipment and processes have become outdated, with low efficiency. Therefore, our company began exploring a new journey in water-based ink printing.

Exploring Water-Based Ink Printing

Water-based flexible packaging printing is a globally challenging project, and there have been no established case studies or standards to refer to. We could only rely on our 30 years of production experience to tackle this global issue.

In 2019, as the COVID-19 pandemic swept across the world, global production capacity and trade were severely impacted. It was under these difficult circumstances that we began to focus on solving the challenges of water-based ink printing.

Initially, we gathered information and samples from water-based ink manufacturers both domestically and internationally to confirm the properties of the raw materials and production processes. Based on the characteristics of water-based ink, we then determined our production plan. The biggest difference between water-based ink and traditional inks is its poor drying ability, making it impossible to print using traditional printing presses. As a result, we modified an old two-color printing machine to experiment with single-color water-based ink printing.

Through improvements to the drying system, we successfully achieved single-color water-based ink printing. During our trials, we summarized the following key insights:

- The drying temperature for water-based ink needs to be approximately 50% higher than that of traditional solvent-based inks.

- The drying air volume needs to be increased by 50%.

- Since the volatility of the water and ethanol mixture is lower, there is no need to control viscosity during the printing process.

A New Process for Water-Based Ink Printing

Based on all our insights, we concluded that water-based ink printing is a completely new process that completely revolutionizes the printing industry. It requires the development of new operating protocols and machine processes.

To better promote environmental printing, we continuously adjust and optimize our production processes to ensure our products meet eco-friendly packaging standards and encourage the adoption of new packaging production technologies.

This marks the beginning of our commitment to reform. For the future of our planet, we will continue exploring various eco-friendly flexible packaging solutions and share our experiences freely, helping this scarred planet rejuvenate.