The lamination process plays a pivotal role in the packaging industry, ensuring products are protected from environmental factors such as moisture, light, and contamination. By creating a protective barrier, lamination not only preserves the integrity of the product but also enhances its shelf life and visual appeal. In this article, we’ll dive into the top three types of lamination processes—solvent-based lamination, solventless lamination, and dry lamination—highlighting their unique advantages, applications, and limitations.

At Zhongjia Printing, we provide top-notch custom flexible packaging that tastefully blends your unique branding concepts with wonderful designs. Whatever your desire to enhance the strength, safety, or appearance of your package, our lamination processes will help your product gain attention without losing the highest quality.

Solvent-Based Lamination

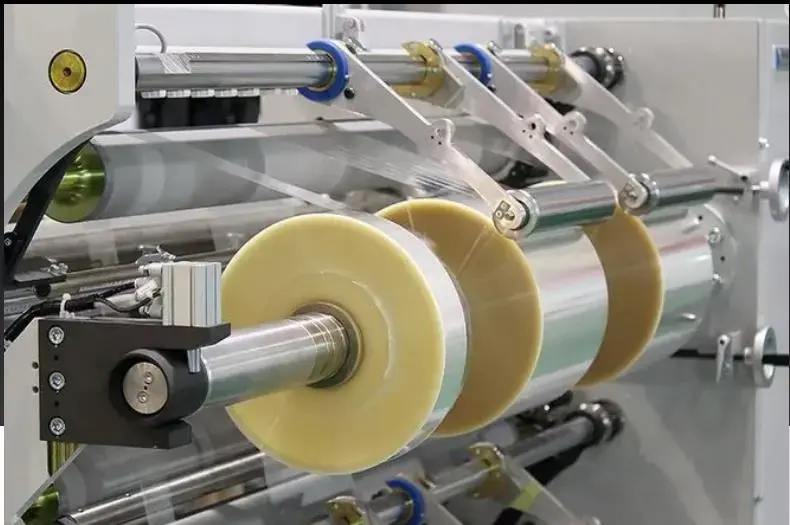

Solvent lamination is also among the most widespread and oldest methods employed in packaging. The adhesive is placed between two sheets of material employing a lost solvent in evaporation during laminating to form a hard adhesive bond between the materials in this lamination. The method is extensively utilized in flexible packaging, particularly in food and medicine.

Advantages of Solvent-Based Lamination

- Long-Term Adhesion: Solvent-based lamination is associated with good and long-term adhesion suitable for packaging materials that are going to be exposed to rough handling, water, and other ambient conditions.

- Types Improved Barrier Properties: It creates an insoluble barrier to water, oxygen, and other conditions which preserves the freshness and shelf life of products.

- Flexibility: It can be applied with many substrates like different films, papers, and foils, and therefore it is extremely versatile for every packaging need.

- Improved Finish: The solvent-based lamination process produces high-quality, mirror-like finishes, improving the finish of the packaging.

Applications & Suitable Applications

Solvent-based lamination is most suitable for applications where product protection is of utmost importance, such as:

- Packaging of Food: Preserves food freshness by providing a high moisture and oxygen barrier.

- Packaging of Drugs: Provides uniform protection to pharmaceuticals that require quality, tamper-evident sealings.

- Cosmetic Packaging: Designs beauty and elegance for products that need to look good for a certain time.

Limitations

- Environmental Issues: Solvent lamination utilizes chemicals that are harmful to the environment when they are treated or disposed of improperly.

- Drying Time is Long: Evaporation of solvents takes a longer time, which can slow down the rate of production compared to other methods.

Solventless Lamination

Solventless lamination employs no solvent whatsoever. The process makes use of some adhesive and this adhesives two layers of packaging material through a chemical reaction or UV curing. The adhesive would otherwise be a two-component system or could even be UV-curable, where it is dried through exposure to ultraviolet rays. Solventless lamination has an environmentally friendly approach to solvent lamination.

Advantages of Solventless Lamination

- Environmentally Friendly: Arguably one of the strongest attributes of solventless lamination is that the ecological footprint is highly reduced with no release of solvents. This renders it the best choice for environmentally conscious brands and regulation compliance in regions where environmental legislation is stringent.

- Faster Production Speed: Compared to solvent lamination, the solventless lamination process does not entail drying time as the adhesive cures instantly and bonds. This means increased production speed and efficiency.

- Excellent Quality Bond: Solventless lamination forms a high-quality, abrasion-resistant bond that lasts long and provides protection to products.

Applications & Suitable Situations

The solventless lamination process is particularly suitable for:

- Food and Drink Packaging: Best for businesses looking for environmentally friendly packaging solutions without compromising quality.

- Cosmetic and Pharmaceutical Packaging: Offers longevity and high-quality finish, which is essential for products that need a professional appearance.

- Green Brands: Best for businesses that are serious about being green and reducing their carbon footprint.

Limitations

- Greater Initial Cost: The equipment that is used with solventless lamination, i.e., UV curing systems, could be more expensive to acquire initially compared to solvent-based systems.

- Curing Precision: The curing process needs to be controlled accurately to yield the highest bonding. Changes in the curing time or power will affect the general quality of the lamination.

Dry Lamination

Dry lamination is one process of lamination that uses dry adhesive film to laminate two layers of material without applying heat, solvents, or chemicals. The adhesive would normally be applied on one of the layers to have it pressed on the other layer atop it to form a strong bond. Dry lamination is mainly used for its flexible packaging applications that need reinforcement with no dangers of heat conversion and chemical risk.

Benefits of Dry Lamination

- Green: Since it does not employ solvents, dry lamination is a green option. It is ideal for companies that would rather maintain a low environmental impact.

- No Heat Exposure: Because no heat is involved in the process, it can be employed for heat-sensitive materials like some papers and films that may be damaged by higher temperatures.

- Flexible: Dry lamination is applicable on a variety of substrates including paper, films, and foils, and therefore flexible to various packaging uses.

- Tough and Durable Bond: Adhesive of dry lamination leaves a rigid grasp which provides long-lasting protection to objects.

Applications & Suitable Scenarios

Dry lamination is commonly used in:

- Snack Packaging: Suitable for products requiring effective barrier properties but are not suitable for high-temperature or solvent exposure.

- Pharmaceutical Packaging: Offers hygienic and clean lamination for medical goods requiring non-toxic and stable packaging.

- Flexible Pouches and Bags: Suitable for goods like pet food or confectionery requiring chemical-free strong bonding.

Limitations

- Barrier Properties: Dry lamination is not as barrier-protective as solvent-based lamination, especially for more serious packaging uses like long-term food storage.

- Limited Substrate Compatibility: Some substrates are less compatible with dry adhesive films, limiting its area of use in comparison to solvent-based lamination.

Zhongjia Printing: Environmentally Friendly, High-Quality Flexible Packaging Manufacturer

The lamination process is important in providing packaging protection with physical and visual benefits. Regardless of your requirements — robust barrier performance, sustainability, or cost-effective production — the appropriate lamination process is vital.

As a top-rated eco-friendly flexible packaging manufacturer, we specialize in offering green package solutions that integrate your brand’s green philosophy. Our lamination technologies, matched with our renewable materials, promise that your packages are not just high-performance packages but also environmentally friendly packages. If you want to maximize product protection and be an early adapter of green packages, call Zhongjia Printing today.