Within the flexible packaging world, selecting the right packaging solution for both product protection and marketing is quite important. Generally, the two prevalent types of packaging are rollstock and pouches. Both have their specific advantages, relating to the product type, the volume of production desired, and the result. In this article, we will show the differences that exist between both, enabling one to make up his mind as to which can be best for his product.

Understanding Rollstock and Pouches

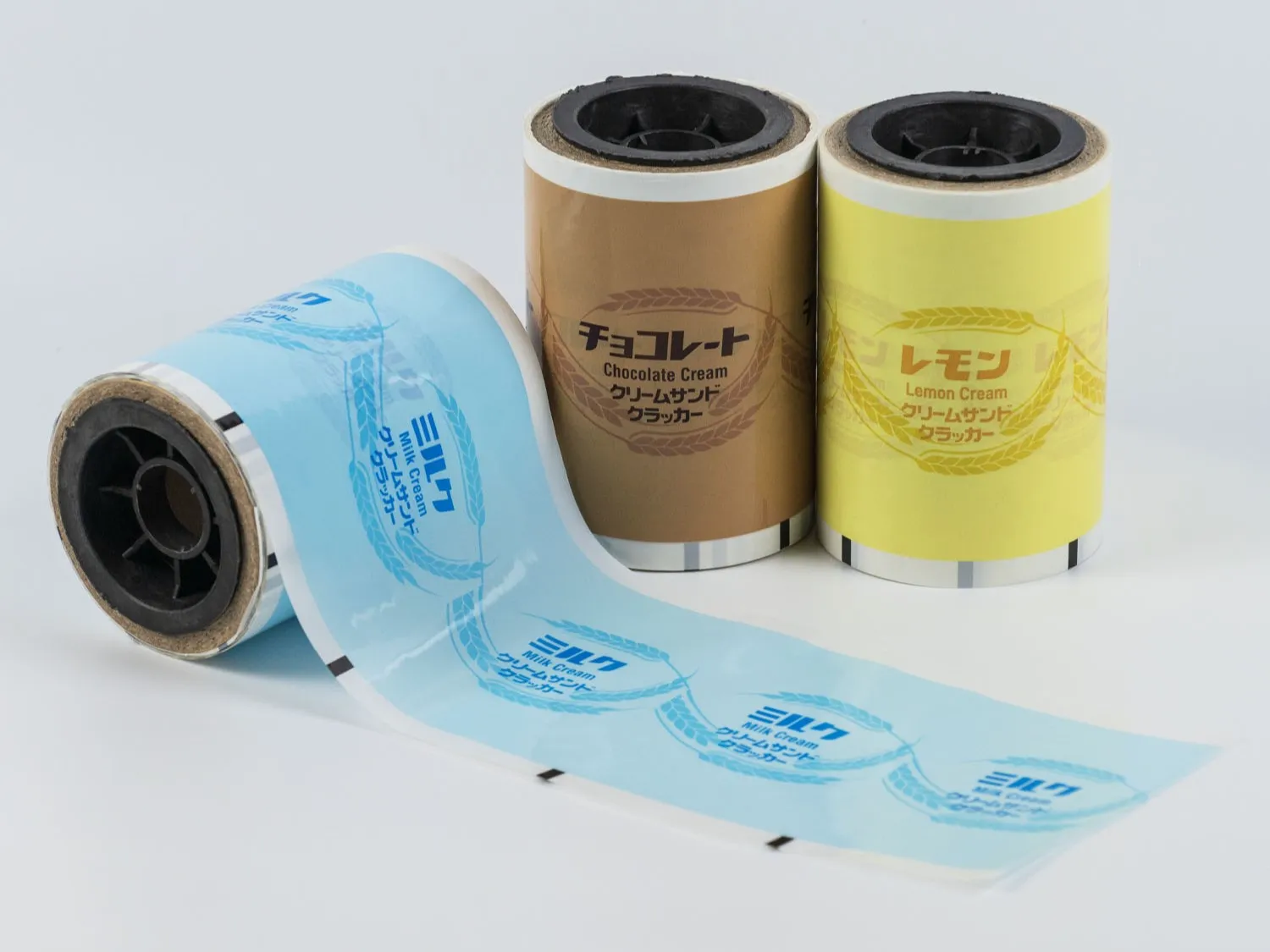

What is Rollstock?

Rollstock refers to large-format rolls of flexible materials that are used by automatic packaging machines. Materials are usually made of films such as polyethylene, polypropylene, or laminated materials. These subsequently feed into machines that form the bags or pouches, fill the product, and seal the package.

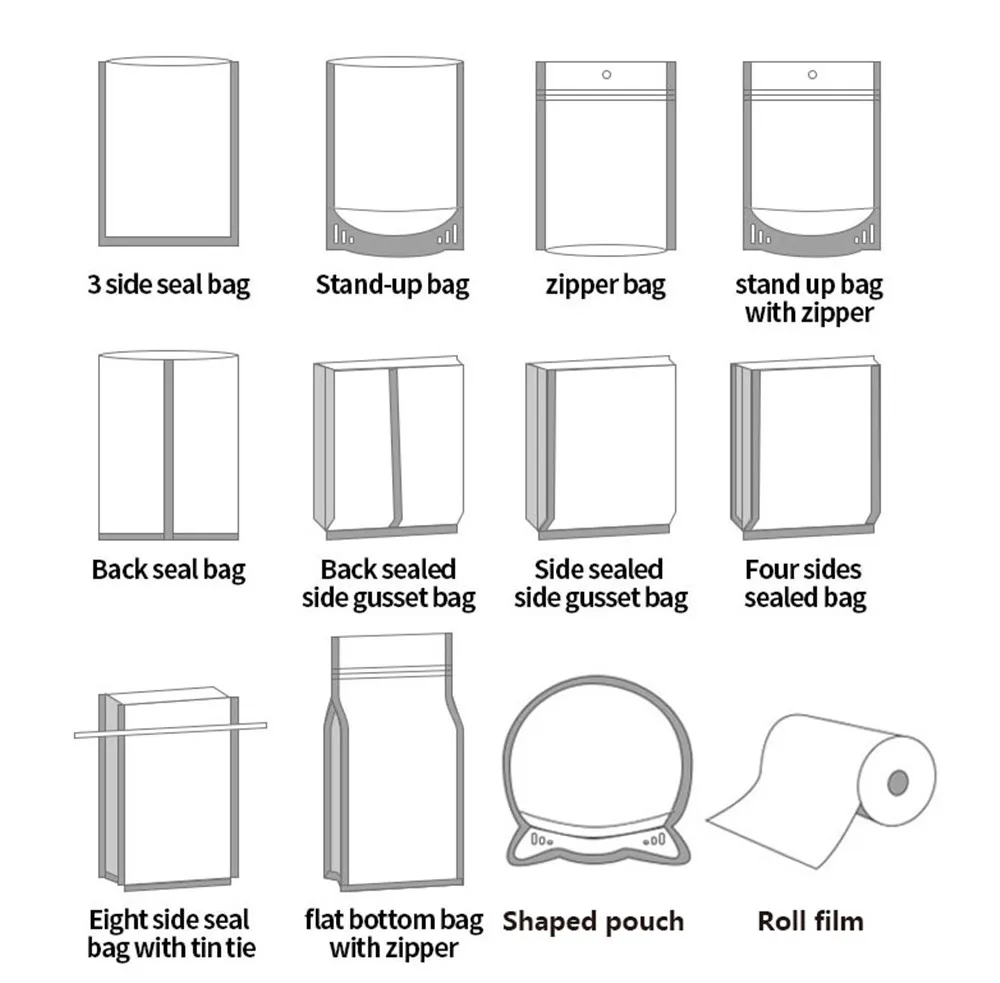

What are Pouches?

Pouches are such bags that come in ready-to-fill-and-seal forms. These are typically used in low-volume operations, which have added features of zippers, spouts, and tear notches. There are a few varieties of pouch types, including stand-up pouches, flat pouches, and gusseted pouches.

Rollstock Packaging: Advantages and Applications

Advantages of Rollstock:

- Cost-Effective: This type of packaging is usually less expensive in a high-volume production process. The material is dispensed in big rolls, hence reducing the cost of packaging per unit.

- Personalization: Rollstock packaging can offer much more variability in design and size. It is easily customizable for different product types.

- Speed and Automation: The rolling stock can be ideal for high-volume production lines, considering that automated machinery can process and package a huge volume of products in a short period.

- Durability: Packaging made from the rolling stock is very durable, providing excellent protection against moisture, light, and air, which is crucial to extending the shelf life of particular products, like snacks, coffee, or even pet food.

Best Suited For:

- High-volume products, such as bulk snacks, grains, or frozen foods.

- Automated packaging lines where speed and cost-efficiency are priorities.

Benefits and Applications of Pouches

Benefits of Pouches:

- Convenience and Usability: Pouches are handier for the end-user. Additional features such as resealable zippers or spouts add functionality and make them more consumer-friendly.

- Branding Visibility: Pouches provide a greater surface area for branding. With a stand-up pouch, for example, one’s product enjoys more visibility in retail on the shelf.

- Eco-Friendly Options: Most pouches are made from recyclable materials that meet the ever-growing demand for eco-friendly packaging options among consumers.

- Portability: Pouches are light in weight and easy to carry; therefore, they can serve as single-serve packaging for beverages, snacks, or even pet food.

Best Suited For:

- Consumer-facing products where convenience and brand recognition are key, such as pet food, beverages, or health supplements.

- Organic food, gourmet items, etc., are produced at low to middle volume and necessitate more niche forms of packaging.

Key Differences Between Rollstock and Pouches

Production Volume

Rollstock is suitable for mass production with a focus on speed and cost-effectiveness; Pouches are suitable for small batches or products that require special features.

Costs

Rollstock is more cost-effective for mass production, while Pouches have a higher individual unit cost, especially when containing features such as zippers.

Flexibility and Customization

Rollstock offers more customization options for a wide range of products, while pouches offers less customization but greater consumer appeal and better brand presentation.

Shelf Presence

Pouches typically have more shelf appeal, with the ability to stand and additional features to attract consumers; Rollstock is simpler in appearance unless processed into a bag.

Factors to Consider When Choosing Rollstock or Pouches

- Product Type: Consider whether your product requires additional convenience, brand presentation, or functionality. For example, liquid products (such as beverages) often require Pouches with nozzles, while dry goods may be better suited to roll stock packaging.

- Production Needs: If your company utilizes a high-volume production line, Rollstock may be the more cost-effective choice. For smaller production runs or products that require customization, Pouches may be a better choice.

- Consumer Demand: In today’s market, consumers are increasingly demanding sustainability and convenience. Pouches with resealable features or eco-friendly materials can fulfill these needs, especially for organic or eco-friendly branded products.

Conclusion: Which Is Right for Your Product?

Ultimately, whether to use roll stock or pouches depends on your particular needs. Rollstock is ideal for high-volume applications with high cost efficiency, especially for products such as snacks and frozen goods. If your focus is on convenience, brand visibility, and consumer-friendly features, pouches offer greater opportunities for differentiation, making them perfect for retail-facing products.

As one of the leading flexible packaging manufacturers, Zhongjia Printing offers both stock and custom solutions for rollstock and pouches, so that your product will be packaged not only efficiently but with the highest quality. Whether you need high-volume packaging or that custom solution for a niche market, we can provide the right packaging that can meet both your production and consumer needs.

Browse through our packaging solutions today and see how we can elevate your product packaging.