Have you ever thought about printing QR codes on your packaging to carry out lottery activities, genuine verification, product traceability, and other functions?

Now, our latest QR code printing technology can print a changeable 2D code directly on flexible packaging, achieving the functionality of “one code per bag.” By scanning this unique QR code, consumers can access information about the product’s production details, ongoing promotions, authenticity verification, and more. This service can be tailored and customized to suit different needs.

So, what exactly is the principle of QR code printing on flexible packaging, and what are its advantages and disadvantages? Zhongjia Packaging is detailed below.

Principle of QR Code Printing Technology

QR code printing is a technology that involves installing a digital nozzle machine onto the existing production line. The machine uses electronic ink to spray patterns, and through a computer-controlled nozzle, it can alter the patterns based on predefined conditions.

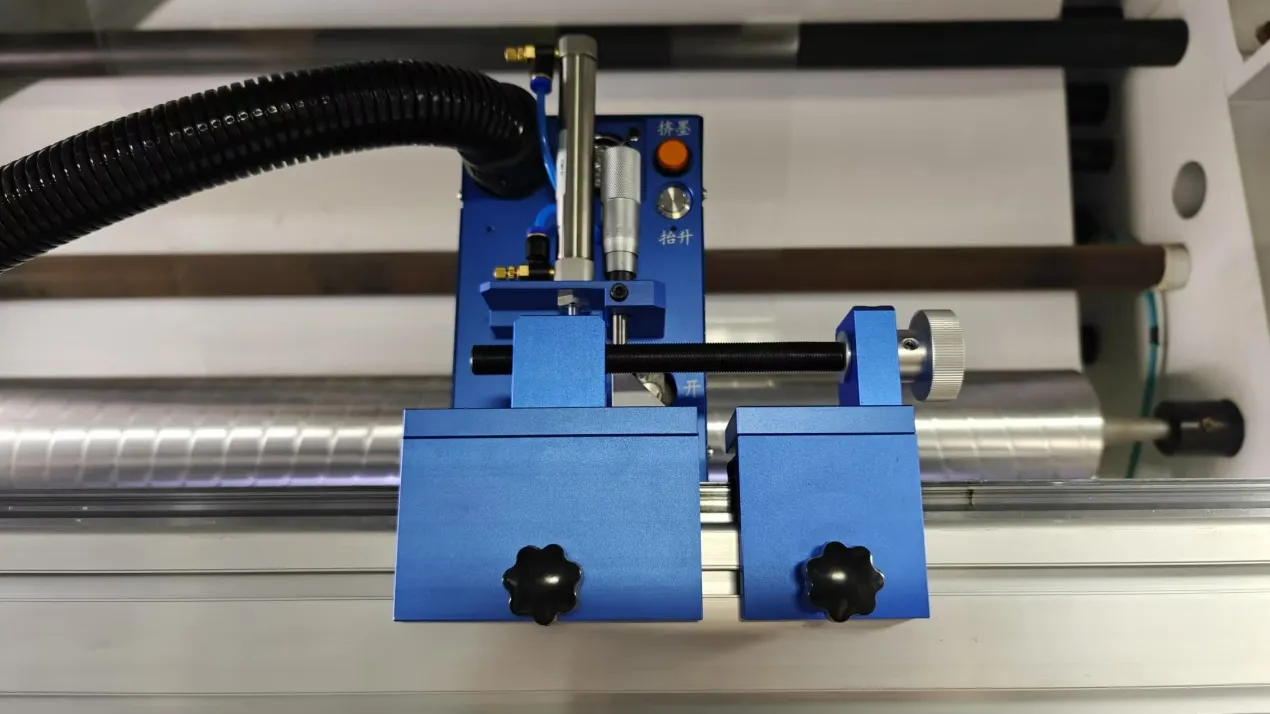

Machine Configuration:

Digital Sprinkler

Various digital nozzles allow for different DPI and spraying speeds. These nozzles create patterns on the film using built-in electronic ink. We use Ricoh’s digital sprinkler, which offers fine spraying, speed, and ease of maintenance. It can achieve up to 350 DPI at a speed of 200m/min, with a spray area of up to 30cmx60cm—suitable for most flexible packaging products.

Control Computer

Our self-developed software controls the QR code printing, allowing us to customize the size, content, and resolution of each QR code. By linking the database to the software, we can generate and print any unique QR code (and each one will be different).

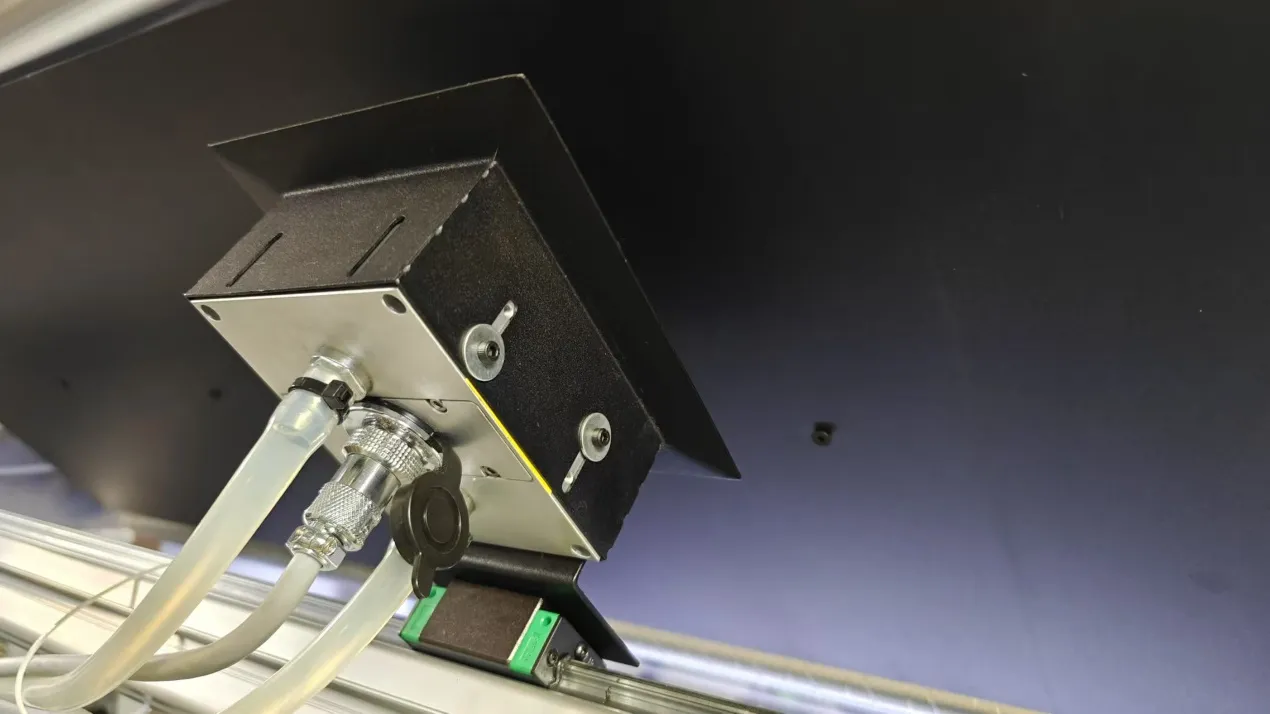

UV Curing Lamp

To dry the printed QR codes on flexible packaging, a UV curing lamp is used. This ensures that the QR codes remain clear and durable, even when produced at high speeds.

Negative Pressure System

To prevent ink pollution, a vacuum system ensures the ink stays tightly contained in the storage tank until needed by the nozzle.

QR Code Printing Positions in Flexible Packaging

There are three primary positions where QR codes can be printed on flexible packaging:

Surface of the Bag

Printed on the exterior, these QR codes are easily erasable. This is suitable for temporary campaigns or when you’re unsure about the QR code’s future use.

Inside the Bag Surface

Printed on the inner surface, these QR codes are permanent and provide anti-counterfeiting features. When scanned, the system generates a unique identifier that is cross-checked with the database to verify authenticity.

Bag Intermediate Layer

This method places the QR code between layers, so it is only visible after the bag is opened. This is often used for promotional activities like raffles, where verification occurs only upon purchase.

Case Study: Enhancing Product Authenticity

A customer needs to identify the authenticity of their bags to prevent others from imitating them.

- At this point, the customer had 50,000 random numbers from 12340 – 102340. At this time, we make the numbers into data packets and input them to the control host for conversion.

- 50,000 random numbers will become 50,000 QR codes, which are randomly arranged in the control host.

- After starting the machine, it will apply paint according to the set position. Until flash stops or the digital library is used up.

- At this time, on the 50,000 bags produced, the QR code of each bag is different. After scanning the QR code, the user will get a string of numbers. After comparing the numbers with the server, the authenticity of the product and the number of scans can be known.

Benefits of Customizable QR Code Printing on Flexible Packaging

The ability to print unique, changeable QR codes on packaging offers numerous advantages:

- Anti-Counterfeiting: Each product has a unique identifier, making it nearly impossible to replicate.

- Product Traceability: Consumers and businesses can trace the product’s journey from production to sale.

- Customization: Brands can customize the packaging with dynamic, interactive QR codes to engage customers with additional features such as loyalty programs, product info, and promotional offers.

Personalized packaging has become a strong competitor in the market. Come and custom flexible pckaging bags according to your own needs.