Gravure printing, also known as intaglio printing, is a high-quality printing technique widely used in the packaging industry. Renowned for its precision and consistency, gravure printing plays a pivotal role in producing premium designs for flexible packaging.

Gravure Printing Process

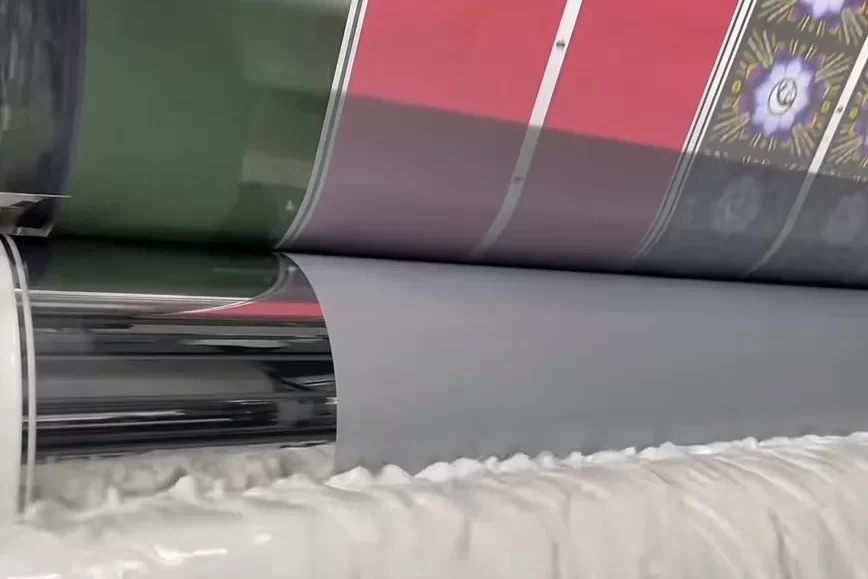

The process of gravure printing makes it possible to produce a concave pattern. The engraving of a picture or text on a printing cylinder does this. A water-based ink is applied to the surface of the printing cylinder at the time of printing, filling the ink in a hollow space in the cylinder.

The material will then go through the cylinder by this method: in transferring the ink stored in recessed areas to the surface of the material, which can be plastic film, paper or aluminum foil. This method ensures high-precision images and excellent print quality. It is considered extremely suitable for packaging printing projects that are in high volumes.

Advantages of Gravure Printing

Best Quality Impressions

The gravure printing performed with water-based inks renders themselves from every angle to excellent color depth and detail and any print results consistent that can withstand even high-volume production. The water-based ink has also excellent adhesion and abrasion resistance, making it the best choice for applications wherein the end product is flexible packaging and requires very high quality printings.

Longevity and Long Runs

Gravure printing machines are very robust and could run even for long periods without any compromise to print quality so that they become a good choice for mass production purposes. Such robust machines make gravure printing a preferred option for long term packaging production.

Versatility with Different Substrates

Gravure printing can handle a wide range of flexible packaging materials, including but not limited to plastic films, aluminum foils, and paper, and is equally suitable for food, label, and everyday item packaging.

Cost-effectiveness

Gravure is quite capital-intensive at purchase; however, it is cheaper than all the other methods, especially as it concerns high-volume production, and in so doing employs water-based inks. Such inks do save the environment and create cost reduction during use.

Difference Between Flexo and Gravure Printing

Gravure printing and flexo printing are both common methods of packaging printing, but they differ greatly in their processes and areas of application.

- Print quality: Gravure printing offers higher image precision and color depth, making it particularly suitable for packages that require high-quality printing. While flexographic printing is highly adaptable, it is slightly less accurate and consistent than gravure printing in mass production.

- Production efficiency: Gravure printing is suitable for mass production, especially in the long time, large-scale production runs show a strong advantage, while flexographic printing is suitable for smaller batches, diversified production needs.

- Applicable materials: gravure printing can handle a variety of complex materials, including film, paper and composite materials, widely used in flexible packaging, while flexographic printing is more suitable for printing simpler materials.

Combining Gravure Printing with Water-based Inks

In addition to guaranteeing a great print result, gravure printing when combined with water-based inks becomes environmentally friendly.

Water-based inks decrease harmful solvent emissions and are the most significant part of environmental packaging.

Modern gravure printing machines provide companies with high-quality, environmentally friendly solutions for packaging printing—particularly when those companies want to produce high volume flexible packages-at higher productivity and environmental benefits.

The Future and Development of Gravure Printing

- Technological innovation: Gravure printing presses are becoming increasingly intelligent and automated, greatly improving productivity while reducing operating costs.

- Environmentally friendly: While water-based ink formulation is further optimized, gravure printing turns out to be a substantial method for companies to work towards sustainability.

- Market expansion: Expansion within the gravure printing sector could be boosted by ever-pressing global demands toward efficiency and environmentally friendly forms of packaging.

Gravure Printing Press Pricing and Selection

Purchasing a gravure printing machineis a key to maintaining high quality production. There are multiple models of gravure printing machines available. Each price varies depending on the size, features, and capacity of the machine. To identify the most efficient gravure printing machine for mass production, it must be efficient but under budget limits, as this affects dramatically the cost of production and product quality.

Conclusion

Gravure printing remains the dominant technology in the packaging industry through its high quality printing results, excellent durability and productivity.

Combined with the use of water-based inks, it not only improves environmental friendliness, but also further consolidates the importance of gravure printing in flexible packaging.