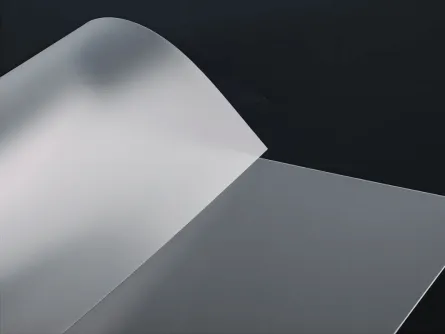

Flexible packaging material plays a crucial role in the market success of a product in the modern-day competitive environment, which ultimately affects the life of the brand itself. Being a flexible packaging manufacturer specializing in water-based ink printing, Zhongjia Printing recognizes the versatility and significance of flexible packaging material. Today, we’ll walk you through a detailed description of 8 different types of flexible packaging materials to enable a suitable selection for various needs. Value addition to a product in terms of market competitiveness and protection will stem from this.

Polyethylene (PE) Film: Low Cost and Most Used

Low cost, high moisture resistance, and durability make the Polyethylene PE film one of the most used flexible packaging materials. It is largely used in food, daily chemical, and pharmaceutical packaging. With good clarity, PE film makes a good option for packaging needs that are not very complex and well-suited for water-based ink printing.

Advantages:

- Cost-effective

- Good moisture resistance

- Recyclable

Applications:

- Food packaging materials: Food and beverage packaging

- Cosmetics, daily chemical products packaging

Polypropylene (PP) Film: Better Clarity And Heat Resistance

Heat resistance and transparency are two crucial aspects of packaging. These are PP films’ strong points when compared to PE films. Because of this, PP film is utilized extensively in packaging that requires transparency and high-temperature resistance. Rest assured, this type of film is most suitable for use in the packaging of premium products, flexible food packaging materials, and other products that require showcasing the contents.

Advantages:

- Excellent transparency

- Good heat resistance and chemical resistance

- UV protection

Applications:

Premium food packaging

Cosmetics, personal care products

Aluminum Foil Laminate: Excellent Barrier And Protection Properties

Aluminum foil laminate is a composite material manufactured by combining aluminum foil with other plastic films such as PE or PET. This laminate protects and preserves the most sensitive of goods. Aluminum foil lamination excels at blocking light, creating gas seals, and preserving everything from food to other flexible packaging materials.

Advantages:

Excellent gas and light-blocking properties

Longer shelf life

High corrosion resistance

Applications:

Pharmaceuticals, health product packaging

Premium food packaging materials

Polyester (PET) Film: High Strength and Widely Used in Beverage Packaging

Polyester (PET) film stands out for its superior strength and heat resistance, and it has an amazing ability to print complex patterns and high-quality images. Because of its good tensile strength and durable nature, PET film is greatly utilized in food and beverage packaging.

Advantages:

- High tensile strength

- Excellent heat and chemical resistance

- Good transparency

Applications:

Beverage and juice packaging

Premium food packaging materials

Nylon (PA) Film: High Temperature Resistance and Strong Protection

Nylon (PA) film is a strong packaging material, which is generally used in products that need to withstand high temperature. Nylon PA film has higher pressure and temperature endurance, strong tearing and abrasion resistance, which is ideal for many high-end or special packaging requirements.

Advantages:

- Excellent temperature resistance

- High tensile strength

- Excellent chemical resistance

Applications:

Food packaging (such as vacuum packaging)

Pharmaceutical packaging

Paper Laminate: Eco-Friendly and Naturally Textured

Paper laminate is made from paper and is manufactured using special techniques that blend well with the environmentally friendly nature of paper packaging and the strength of plastic films. This form of packing material is becoming more sought after, mainly in the high-end food packaging and eco-friendly products separating packaging.

Advantages:

Biodegradable, eco-friendly

Good printability

Premium feel

Applications:

Premium food packaging

Eco-friendly product and gift packaging

EVOH (Ethylene-Vinyl Alcohol) Film: Powerful Barrier, Extends Shelf Life.

EVOH film is a primary material to encapsulate items and cover those which would need to, for a long time, resist penetrable gas and moisture, which need very high gas barrier properties. Foods are most often vacuum packed or placed in MAP packaging for long-lasting shelf life and EVOH film is the best at achieving this.

Advantages:

- Extremely high gas barrier properties

- Extends food shelf life

- Excellent moisture resistance

Applications:

Vacuum packaging

Premium food packaging materials, snack packaging

Biodegradable Film: An Eco-Friendly Packaging Solution

As consumers and shoppers become more conscious of the environment, plastic waste has become a prominent issue. Biodegradable films are made of renewable resources that decompose and don’t contribute to the waste issue. These films are relatively wider in demand and use due to their eco-friendly properties even though they are mostly expensive. Their growth is required in the flexible packaging branch of the industry.

Advantages:

Biodegradable, eco-friendly

Reduces environmental pollution

Enhances the brand’s eco-friendly image

Applications:

Eco-friendly product packaging

Food packaging and daily chemical product packaging

How to Choose the Right Flexible Packaging Material?

Aspects like the target markets, product features, and environmental concerns have to be taken into account. Do pay attention to these parameters during selection:

- Product Specifications: Think about the protective functions that the packaging materials may impose, for example, moisture resistance, anti-oxidation, light blocking, and so on.

- Printability: Different materials have different degrees of printability. The designed materials should properly represent the company’s image.

- Environmental Considerations: Meeting modern-day environmental standards can be supported by choosing recyclable or biodegradable packaging materials and can further enhance the green image of the brand.

- Cost vs. Effectiveness: Carefully consider the balance between pricing and packaging performance when selecting the material.

Conclusion

With an increase in the size of the flexible packaging market, new material varieties and technologies are growing in number. As a custom flexible packaging supplier, Zhongjia Printing has over three decades of experience and can back up your eco-friendly flexible packaging needs.